Overview

dhPlus is affordable conveyor and warehouse control for small to medium size systems. It can be used for a wide range of conveyor applications and can utilize many field devices including barcode scanners, weigh scales, dimensioners and P&A (Print and Apply) units.

dhPlus can also communicate with host systems such as SAP for intelligent package routing and tracking through the warehouse or plant.

The latest version is 1.11.

Pricing

Turnkey pricing for dhPlus deployments range from about $50K to $1M. It is more cost effective than all of the large system integrators and many of the smaller ones.

What's included

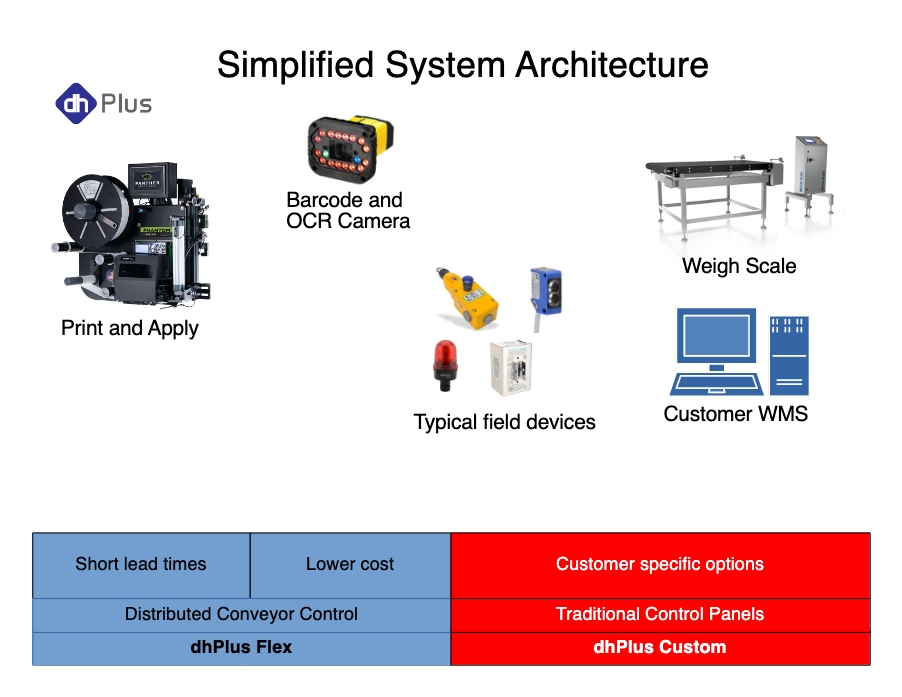

The best way to think about dhPlus is as a customizable hardware and software product that will control a customer's conveyor system. It has two main options -- Flex and Custom. Flex is our standard distributed configuration while Custom has traditional control panels and caters to customer special requests. See the Feature Matrix below.

dhPlus typically ships with the following:

- One or more control pedestals (for Flex) or traditional control panels (for Custom) with high capability PLCs (Programmable Logic Controller) to control the conveyor system.

- One or more HMIs (Human Machine Interface) mounted on the pedestal or control panel door. The HMIs are used to control and monitor the conveyor system.

- One or more industrial PCs for the WCS (Warehouse Control System) mounted in the pedestal or control panel. The PCs have battery backup and do not run Windows for added security and reliability.

- Field devices such as photo eyes, proximity switches, E-stop pull cords, pushbutton stations, air pressure sensors and motor disconnect switches. For Flex, motor starters and VFDs are also field mounted.

Optional equipment that can be shipped with dhPlus include barcode camera stations, dimensioners, P&A (Print and Apply) units, and a maintenance support laptop. See simplified architecture diagram below.

Features

The feature matrix below outlines all of the main hardware and software features.

Additional hardware and customized software can be added to perfectly fit a customer's functional requirements.

| Feature | HW/SW | Flex | Custom |

|---|---|---|---|

| Full height control pedestal. Can have multiple pedestals per system. | HW | X | |

| HMI mounted on face of control pedestal | HW | X | |

| Control panel (traditional 1 or 2 door). Can have multiple panels per system. | HW | X | |

| HMI mounted on panel door | HW | X | |

| WCS capable PLC (AutomationDirect Productivity 1000 or Click Plus with Node-RED Module) | HW | X | |

| WCS capable PLC (AutomationDirect Productivity 2000 or 3000) | HW | X | |

| Allen Bradley CompactLogix PLC (special customer request) | HW | X | |

| Industrial PC with super cap backup (mounted in control pedestal or control panel) | HW | X | X |

| Fixed speed motor control (Field mounted for Flex, Panel mounted for Custom) | HW | X | X |

| Variable speed motor control -- VFD (Field mounted for Flex, Panel mounted for Custom) | HW | X | X |

| MDR interface using PLC I/O or network communications | HW | X | X |

| Safety circuit (E-stop buttons and pull cords) | HW | X | X |

| Photo eyes (for sensing the carton or pallet) | HW | X | X |

| Proximity or limit switches (for sensing the position of gates and other conveyor parts) | HW | X | X |

| Motor disconnect switches (mounted near conveyor) | HW | X | X |

| Barcode scanning cameras (Cognex or IFM) | HW | X | X |

| Dimensioner cameras (Cognex) | HW | X | X |

| OCR (Optical Character Recognition) cameras (Cognex or IFM) | HW | X | X |

| Print and Apply applicators (Panther) | HW | X | X |

| Main conveyor control logic | SW | X | X |

| Pick module routing logic | SW | X | X |

| High speed sortation logic | SW | X | X |

| MDR accumulation and sortation logic (Itoh Denki, PulseRoller, Interroller or Hytrol) | SW | X | X |

| P&A (Print and Apply) interface logic | SW | X | X |

| Weigh scale interface logic | SW | X | X |

| Host interface (FTP protocol) | SW | X | X |

| Host interface (Custom socket protocols -- TCP or UDP) | SW | X | X |

| Host interface (MQTT protocol) | SW | X | X |

| Host interface (Industrial ModbusTCP or Ethernet/IP protocols) | SW | X | X |

| Host interface (Database table sharing) | SW | X | X |

| Host interface (Web API) | SW | X | X |

| HMI standard screens for control, configuration and monitoring | SW | X | X |

| HMI conveyor graphics | SW | X | X |

| HMI dashboard | SW | X | X |

| HMI event logging | SW | X | X |

| HMI alarming | SW | X | X |

| Advanced WCS screens with database views (Node-RED Web HMI only) | SW | X | X |

| Email notifications | SW | X | X |

| SMS notifications | SW | X | X |

| Customer support laptop with all software preloaded | HW/SW | X | X |

| Mobile device support for Android (App for C-more, Web for Node-RED) | SW | X | X |

| Mobile device support for iOS (App for C-more, Web for Node-RED) | SW | X | X |

| Security (C-more HMI) | SW | Passcode | Passcode |

| Security (Web HMI with login enabled) | SW | HTTPS | HTTPS |

| SQL database (Industrial PC required) | SW | X | X |

Ready for a quote?

Please reach out to David at david@denharing.net or call 404-993-6973 when you're ready for a budgetary or firm quote for your specific application.